|

MATERIAL:

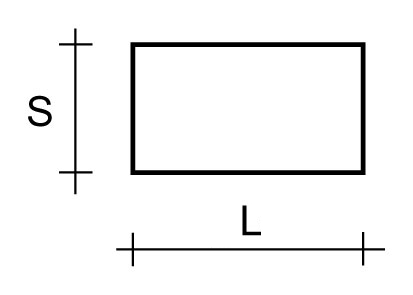

AISI 01, 1.2510 Tool steel for cold processes C= 0.95 Si= 0.20 Mn= 1.20 Cr= 0.60 W= 0.60 V= 0.10 Example of designation: GFS 25 x 8 x 500 - 01 |

s= thickness

L= width LENGHT: 500 mm |

|

|

|||||||||||||||||||||||||||||

SUPPLIED

SUPPLIEDSupplyed annealed

Free of decarburization

Maximum hardness obtainable 63 HRC

AVAILABLE DIMENSIONS

Lenght 500 mm

Section: see dimension table

Thickness tolerance

+ 0,05 / -0,00

Width tolerance

+ 0,2 / -0,0

Lenght tolerance

+ 5 / -0

MATERIAL:AISI 01, 1.2510

Tool steel for generic use, hardenable in oil, not subject to deformations.

Thermal treatment on this kind of tool steel for cold processes is less complicated than others at higher alloy.

THERMAL TREATMENT:

Hardening in oil

Preheat up to 300/500 °C before reaching hardness temperature of 780/820 °C.

Tempering

proceed with temperatures between 150 °C and 350 °C according to the usage needs and referring to the tempering curve.

Ex. 1 hour at 150° = hardness HRC 63-64

Ex. 1 hour at 200° = hardness HRC 61-62

Ex. 1 hour at 250° = hardness HRC 58-60

Ex. 1 hour at 300° = hardness HRC 54-56

PACKAGING

Bars are always supplied oiled and individually packaged to avoid and prevent damage during handling and transport.

APPLICATIONS

Dies medium passage, tools for particular presses, punches for drawing, pins, bushes, bits for lathe, lathe jaws, engraving cutters, blades for tear-off machines, calibrated caps, threaded gauges and precision tools as cams, blade to cut the fabric, reamers, collets, knife cutters, cut strips, trimmers, expander rollers, plastic moulds, accessories for moulds and knives for wood processing.